The tanker simulation unit with valve is a critical tool for cleanout valve training, offering a safe environment to practice skills without live system risks. This unit replicates real-world scenarios, allowing trainees to gain hands-on experience with various valves and procedures, enhancing safety and efficiency in managing hazardous materials and adhering to industry regulations. The Betts Setup revolutionizes training by providing immersive simulations, fostering proficiency and preparedness for unexpected situations in industrial or maritime operations.

“Discover the power of efficient training with the Cleanout Valve Training Kit featuring Betts Setup. This comprehensive guide delves into the world of tanker simulation, offering a clean start for professionals and newcomers alike. By understanding tank operations through simulation, you can unlock optimal performance. The kit’s essential tools, including the Betts Setup, empower users to master valve cleaning techniques. From real-world application to enhanced safety measures, this article explores how on-site training enhances skills in operating tanker simulation units with valves.”

- Understanding Tanker Simulation: A Clean Start

- Betts Setup: Unlocking Efficient Training

- Components: The Kit's Essential Tools

- Step-by-Step Guide: Mastering Valve Cleaning

- Benefits: Enhancing Safety and Performance

- Real-World Application: On-Site Training Value

Understanding Tanker Simulation: A Clean Start

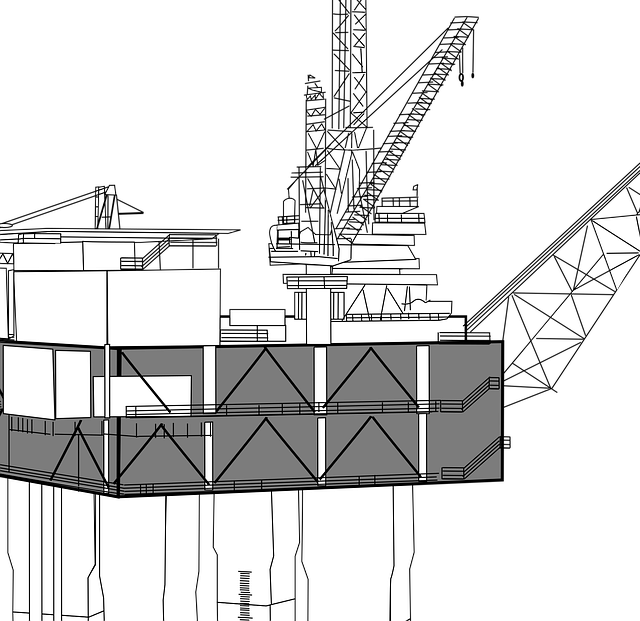

Starting your journey in cleanout valve training involves understanding the essence of a tanker simulation unit with valve. This simulated environment provides a safe, controlled space to practice critical skills required for maintaining and operating cleanout valves in actual tankered vehicles. By replicating real-world scenarios, trainees gain hands-on experience without the risks associated with live systems.

The tanker simulation unit with valve serves as a powerful tool for training, allowing participants to familiarize themselves with various valve types, their functions, and the specific procedures for cleanout operations. This foundational knowledge is crucial for ensuring safe and efficient management of hazardous materials, as well as compliance with industry regulations.

Betts Setup: Unlocking Efficient Training

The Betts Setup is a game-changer in cleanout valve training, offering an innovative approach to efficient learning and skill development. This system simulates real-world scenarios, particularly within the context of a tanker simulation unit with valve, allowing trainees to gain practical experience in a controlled environment. By replicating the intricate mechanics and challenges of valve operation, the Betts Setup provides a comprehensive training solution.

With its advanced technology, this setup enables users to navigate complex labyrinthine tasks, enhancing their understanding of valve systems. Trainees can practice opening, closing, and adjusting valves, learning to respond swiftly and accurately in various situations. This immersive training fosters confidence and preparedness, ensuring individuals are ready to tackle unexpected challenges during actual operations, making it an invaluable asset for any industrial or maritime setting.

Components: The Kit's Essential Tools

The Cleanout Valve Training Kit is equipped with a diverse set of tools essential for mastering valve maintenance, particularly in the context of tanker simulations. At its core, the kit includes a tanker simulation unit with valve, meticulously designed to replicate real-world tankering scenarios. This component allows trainees to gain hands-on experience in a controlled environment, safely practicing complex cleaning and valve manipulation procedures.

Complementing this is an array of other tools tailored for comprehensive training. From specialized wrenches and gauges to cleaning solutions and accessories, each element plays a crucial role in preparing individuals for the challenges they may encounter during actual tank maintenance operations. This well-rounded approach ensures that trainees develop a proficient understanding of valve systems, enhancing their readiness for on-the-job responsibilities.

Step-by-Step Guide: Mastering Valve Cleaning

Mastering valve cleaning is a crucial skill for any professional navigating the world of industrial maintenance. Start by gathering your tools, including the cleanout valve training kit featuring Betts setup. This comprehensive kit includes a tanker simulation unit with valves designed to replicate real-world scenarios. Next, familiarize yourself with the kit’s components: a variety of valves, cleaning solutions, and brushes tailored for different types of debris.

Begin with a thorough inspection. Identify the specific valve and its mechanism. Follow these steps sequentially: disassemble the valve carefully, ensuring no cross-contamination between parts; clean each component individually using the appropriate brush and solution; reassemble, lubricate if needed, and test the valve’s functionality in the simulation unit. Regular practice will transform this process into second nature, ensuring optimal valve performance and minimizing downtime for industrial operations.

Benefits: Enhancing Safety and Performance

The cleanout valve training kit, featuring a Betts setup, offers significant advantages in enhancing both safety and performance for professionals working with tanker simulations involving valves. By immersing yourself in realistic scenarios using this kit, you gain invaluable hands-on experience that translates directly into improved operational efficiency. The ability to practice complex valve operations in a controlled environment promotes safer work practices, reduces the risk of errors, and ensures that when faced with real-world challenges, every movement is deliberate and precise.

Moreover, the integration of a tanker simulation unit with valve mechanisms allows for dynamic training sessions that mimic the nuances of actual tankering operations. This comprehensive approach to learning not only sharpens your technical skills but also fosters a deeper understanding of system interdependencies, ultimately contributing to smoother and more effective tank maintenance and management.

Real-World Application: On-Site Training Value

In real-world industrial settings, the cleanout valve training kit featuring a Betts setup offers immense value through on-site training advantages. This innovative toolkit allows professionals to simulate various tanker scenarios right at their operational sites, ensuring personnel are well-prepared for any unexpected situations involving tank valves. By replicating complex valve operations in a controlled environment, workers can gain practical experience without the risks associated with live demonstrations.

The on-site training aspect is particularly crucial for maintaining efficient and safe operations in the oil and gas, chemical processing, or maritime industries where tankers play a vital role. With this kit, companies can train employees effectively, enhance their problem-solving skills, and boost overall operational readiness, all while minimizing downtime and potential hazards often associated with traditional off-site training methods using a tanker simulation unit with valve.