In the critical domain of industrial operations, particularly within ports and refineries, safe and efficient tanker product transfers are essential but require specialized training due to the risk of hazardous liquid spills. Traditional methods lack practical elements, leaving employees unprepared for real-world crises. Tanker product transfer simulators offer a secure, controlled environment for trainees to learn complex tasks, emergency response, and spill control techniques without risking accidents or environmental harm. These simulators accurately replicate real-world operations, enhancing safety, efficiency, and cost-effectiveness in maritime training. Key features include realistic physics simulations, advanced modeling, integrated safety protocols, and customizable modules. Implementing these simulators is a strategic approach to enhance safety standards and operational efficiency in hazardous material handling.

In today’s maritime industry, effective spill control training is paramount to mitigate environmental hazards during tanker product transfers. The need for realistic simulations cannot be overstated, leading to the advent of advanced tanker product transfer simulators. These innovative tools offer a safe, controlled environment for mariners to hone their skills in managing potential spills. By employing these simulators, shipping companies can significantly enhance safety, reduce risks, and ensure compliance with stringent environmental regulations. This article explores the crucial aspects of spill control training using tanker product transfer simulators.

- Understanding the Need for Spill Control Training

- What is a Tanker Product Transfer Simulator?

- Benefits of Using Simulators for Offload Training

- Key Features to Consider in a Tanker Transfer Simulator

- Implementation and Best Practices for Effective Training

- Real-World Impact: Success Stories of Spill Control Training

Understanding the Need for Spill Control Training

In the realm of industrial operations, especially in ports and refineries, safe and efficient tanker product transfer is paramount. However, accidents involving hazardous liquid spills can have devastating environmental and economic impacts. This underscores the crucial need for comprehensive spill control training among personnel involved in these processes. Traditional training methods often fall short due to their limited practical components, leaving employees ill-prepared for real-world scenarios.

Enter the tanker product transfer simulator—a cutting-edge tool revolutionizing offload training. These simulators offer a safe, controlled environment where trainees can navigate complex tasks, respond to emergencies, and master spill control techniques without putting themselves or the environment at risk. By replicating the intricacies of real-world operations, these simulators ensure that when an actual emergency arises, employees are equipped with the knowledge and skills needed to mitigate potential disasters effectively.

What is a Tanker Product Transfer Simulator?

A Tanker Product Transfer Simulator is a sophisticated training tool designed to replicate the complex process of transferring liquid cargo between vessels, often in challenging marine environments. This advanced technology offers a safe and controlled setting for seafarers to gain practical experience in handling various tanker product transfer operations. By simulating real-world scenarios, the simulator enables trainees to learn and refine their skills without risking potential accidents or environmental hazards associated with live drills at sea.

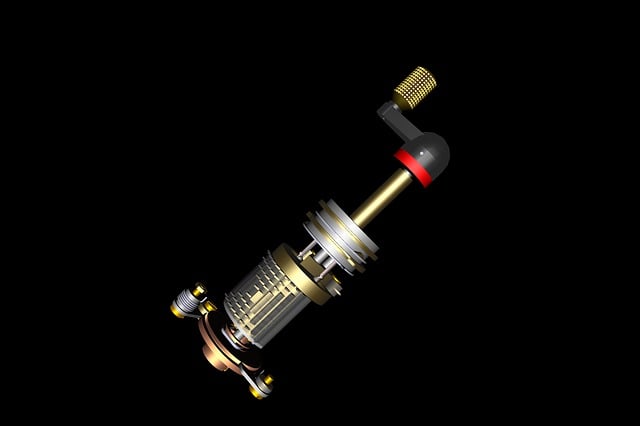

The primary purpose of such simulators is to optimize training programs for marine professionals involved in oil and chemical transportation. They enable efficient practice of critical tasks like pipeline connection, cargo management, and emergency response procedures. With customizable settings, users can encounter diverse challenges, from managing different fluid properties to navigating through tight turns or dealing with system failures, all while receiving immediate feedback on their actions.

Benefits of Using Simulators for Offload Training

Using a tanker product transfer simulator for offload training offers significant advantages in safety, efficiency, and cost-effectiveness. These simulations replicate real-world scenarios, allowing maritime professionals to practice complex operations without risking human error or environmental damage. By familiarizing themselves with the intricacies of tanker product transfer processes, crew members can enhance their coordination and decision-making skills, ensuring smoother and safer operations during actual cargo handling.

Moreover, simulators provide a controlled environment where trainees can experiment with different variables, such as weather conditions, equipment malfunctions, and emergency situations. This hands-on experience is invaluable, empowering crew members to respond promptly and effectively when confronted with challenges at sea. With continuous training through tanker product transfer simulators, maritime companies can maintain high standards of safety and operational efficiency, ultimately contributing to a more robust and resilient industry.

Key Features to Consider in a Tanker Transfer Simulator

When choosing a tanker product transfer simulator, look for key features that mirror real-world conditions to ensure effective offload training. These include realistic physics simulations, allowing trainees to experience the forces and dynamics of liquid transfers. Advanced modeling of tanker structures and piping systems is crucial for accurate representation of complex operations.

Additionally, seek out simulators with integrated safety protocols and emergency scenarios. This prepares personnel for potential hazards and reinforces adherence to safety standards during high-pressure situations. User-friendly interfaces and customizable training modules are also essential, enabling tailored lessons and efficient progress tracking for each trainee.

Implementation and Best Practices for Effective Training

Implementing a spill control simulator, such as a tanker product transfer simulator, for offload training is a strategic move to enhance safety and efficiency in hazardous material handling. This advanced training tool replicates real-world scenarios, allowing trainees to experience potential spills and learn effective containment and cleanup procedures without putting themselves or the environment at risk.

Best practices for leveraging this technology include tailored scenario design, regular updates based on industry standards and new spill response techniques, and hands-on interaction. Trainees should be encouraged to experiment in a controlled environment, fostering critical thinking and decision-making skills. Additionally, integrating multimedia elements, like realistic visual effects and audio cues, can elevate the training experience, making it more immersive and memorable.

Real-World Impact: Success Stories of Spill Control Training

In today’s digital era, the need for effective spill control training has never been more critical. Real-world incidents involving tanker product transfers have highlighted the crucial role that proper simulation plays in mitigating risks and ensuring safety. Success stories abound of companies who have embraced tanker product transfer simulators as a game-changer in their offload training programs. These simulations offer a vibrant, bustling environment where “folks” can navigate complex labyrinths of spill scenarios, fostering a deep understanding of response protocols.

By utilizing these advanced tools, workers gain invaluable experience in handling various types of spills, from modest to massive. The impact is indelible; employees emerge with enhanced confidence and proficiency, ready to face challenges head-on. This practical training translates into improved safety records, reduced environmental impact, and cost savings for companies across the globe. It’s a testament to the power of technology in revolutionizing spill control measures.