The repair industry has undergone a significant transformation, transitioning from traditional to modern techniques driven by demands for efficiency, accessibility, and sustainability. Advanced technologies like 3D printing and robotics offer substantial cost savings without compromising quality. Digital design software streamlines processes, reduces material waste, and minimizes errors, fostering an eco-friendly and rapid repair ecosystem. Embracing cost-effective methods saves money for individuals and businesses, promotes environmental sustainability, and enhances public image. Modern techniques, including 3D printing, AI diagnostics, and robotic precision, revolutionize repairs, making them faster, more efficient, and environmentally friendly, while staying competitive in a dynamic market.

In today’s fast-paced world, traditional repair methods are undergoing a transformative shift towards innovative and modern techniques. This article explores the evolving landscape of repairs, highlighting the benefits of cost-effective solutions for both individuals and businesses. From advanced technologies to successful case studies, we delve into how these new approaches not only enhance efficiency but also contribute to sustainability. By understanding these changes, readers will gain insights into the future of repair services, where cost-effectiveness is a driving force.

- Understanding Modern Repair Techniques: A Shift from Traditional Methods

- The Benefits of Cost-Effective Repairs for Individuals and Businesses

- Advanced Technologies Driving Innovation in Repair Processes

- Case Studies: Successful Implementation of Modern Repair Techniques

- Overcoming Challenges: Common Obstacles and Their Solutions

- Future Trends: Where Does the Field of Repair Head Next?

Understanding Modern Repair Techniques: A Shift from Traditional Methods

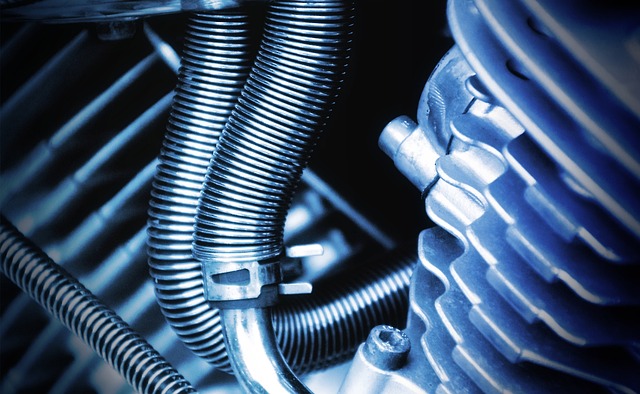

In recent years, the field of repair techniques has undergone a significant transformation, shifting away from traditional methods towards innovative and modern approaches. This shift is largely driven by the need for more efficient, accessible, and cost-effective solutions, especially in an era where sustainability and quick turnaround times are paramount. Modern repair techniques leverage advanced technologies such as 3D printing, robotic assistance, and digital design software to achieve precision and speed unmatched by older methods.

Compared to conventional repair processes that often involve laborious manual work and expensive tools, modern techniques promise substantial cost savings without compromising quality. For instance, 3D printing allows for the rapid prototyping of parts, reducing lead times and material waste. Robotic systems enhance accuracy and consistency, minimizing errors and the need for specialized human labor. These innovations collectively contribute to a more sustainable and efficient repair ecosystem, making modern methods not just an improvement but a necessity in today’s fast-paced world.

The Benefits of Cost-Effective Repairs for Individuals and Businesses

For both individuals and businesses, embracing cost-effective repair techniques offers a multitude of advantages. One of the most significant benefits is financial savings. Traditional repair methods can be expensive, often involving high labor costs and the use of specialized equipment or materials. In contrast, modern, innovative repairs focus on efficiency and accessibility, reducing overall expenses. This affordability makes it feasible for people to undertake minor repairs themselves, extending the lifespan of their possessions and cutting down on maintenance budgets.

Moreover, cost-effective repairs contribute to a more sustainable and environmentally friendly approach. By encouraging the reuse and repurposing of materials, these techniques minimize waste and reduce the demand for new resources. For businesses, this translates into lower operational costs and a positive public image as eco-conscious entities. It also fosters a culture of resourcefulness and self-reliance, empowering individuals to take ownership of their possessions and contribute to a circular economy.

Advanced Technologies Driving Innovation in Repair Processes

In today’s digital era, advanced technologies are revolutionizing repair processes and making them more efficient and cost-effective. Techniques like 3D printing, for instance, enable precise customization of replacement parts, reducing waste and lowering production costs. Furthermore, the integration of artificial intelligence (AI) and machine learning algorithms enhances diagnostic accuracy, allowing technicians to identify issues swiftly and accurately. This translates into faster repair times and minimized material wastage.

These innovative approaches not only streamline repair operations but also contribute to sustainability by optimizing resource utilization. By leveraging cutting-edge technologies, repair businesses can stay competitive in the market while offering high-quality services that cater to modern demands.

Case Studies: Successful Implementation of Modern Repair Techniques

In recent years, the application of modern repair techniques has led to remarkable transformations in various industries. These innovative approaches are reshaping traditional methods and offering numerous benefits, particularly in terms of cost-effectiveness. Case studies from around the globe highlight successful implementations that have resulted in significant savings for businesses without compromising quality.

For instance, automotive manufacturers have adopted advanced welding technologies and 3D printing to repair and remanufacture parts, reducing material waste and labor costs. Similarly, construction companies are leveraging drones and robotic systems for precise inspection and repair of infrastructure, minimizing project delays and expenses. These modern techniques not only enhance efficiency but also contribute to a more sustainable and environmentally friendly approach to repairs.

Overcoming Challenges: Common Obstacles and Their Solutions

In the realm of repair techniques, overcoming challenges is a pivotal aspect of staying ahead in an ever-evolving landscape. Common obstacles include material costs, accessibility issues, and ensuring long-lasting repairs. One innovative solution to tackle these hurdles is adopting digital technology for precision measurements and remote consulting. By leveraging advanced tools like 3D scanning and virtual reality, technicians can accurately assess damage from a distance, reducing on-site travel expenses and minimizing disruption to clients’ schedules.

Furthermore, modern repair techniques emphasize customization and adaptability. Pre-fabricated parts may not always fit perfectly, leading to additional adjustments and costs. To overcome this, some companies are embracing modular design principles, creating interchangeable components that can be easily tailored to specific needs. This approach not only streamlines the repair process but also makes it more cost-effective, as standardized parts reduce waste and simplify inventory management.

Future Trends: Where Does the Field of Repair Head Next?

The future of repair is poised for a significant transformation, driven by advancements in technology and a growing emphasis on sustainability. One prominent trend is the adoption of digital tools and automation, which can streamline the repair process, making it faster and more efficient. AI-powered diagnostics can quickly identify issues, while robotic arms equipped with precision instruments could perform intricate repairs, reducing human error and labor costs.

Additionally, the circular economy concept is expected to gain traction, promoting a repair-focused mindset over disposability. This shift will encourage manufacturers to design products for longevity and ease of repair, making it more accessible and cost-effective for consumers to maintain their goods. As a result, we can anticipate a closed-loop system where repaired items are reintegrated into the production chain, reducing waste and environmental impact.