Tank truck leak training props, specifically the small-scale simulator, are vital tools for preparing professionals in transportation, logistics, and environmental sectors to handle hazardous material leaks safely. By replicating real-world scenarios without risk, this versatile aid enhances readiness, familiarizes teams with various leak situations, boosts confidence, and improves response times. It's ideal for refineries and chemical plants, offering cost-effective, hands-on training that improves coordination, refines emergency procedures, and minimizes environmental impacts through controlled practice of leak response protocols.

“In the realm of industrial safety, understanding and mitigating tank truck leaks is paramount. This article introduces the small-scale tank truck leak simulator unit—a revolutionary tool for enhancing safety protocols. By emulating real-world scenarios, this compact simulator offers an effective solution for training personnel in leak detection and response. With its versatile design and practical applications, it becomes an indispensable ‘tank truck leak training prop’ for any organization aiming to fortify its emergency preparedness.”

- Understanding Tank Truck Leak Training Prop: The Essential Tool for Safety

- Design and Functionality of a Small-Scale Simulator Unit

- Benefits and Applications in Real-World Scenarios

Understanding Tank Truck Leak Training Prop: The Essential Tool for Safety

In the realm of industrial safety, particularly within the transportation sector, tank truck leak training props serve as indispensable tools for preparing professionals to handle potential hazards effectively. These simulated leak scenarios replicate real-world conditions, allowing operators and maintenance personnel to practice responding to leaks without risking exposure to hazardous materials or disrupting operations. By mastering leak containment procedures through such training, teams can significantly mitigate risks associated with tank trucks, ensuring the safety of both personnel and the environment.

The significance of a well-equipped tank truck leak training prop is evident in its ability to enhance readiness levels. It enables practitioners to familiarize themselves with various types of leaks, the appropriate use of spill containment equipment, and efficient coordination during emergency responses. Such training not only boosts confidence but also ensures that should an actual leak occur, teams are prepared to act swiftly and effectively, minimising potential damage and ensuring a swift return to normal operations.

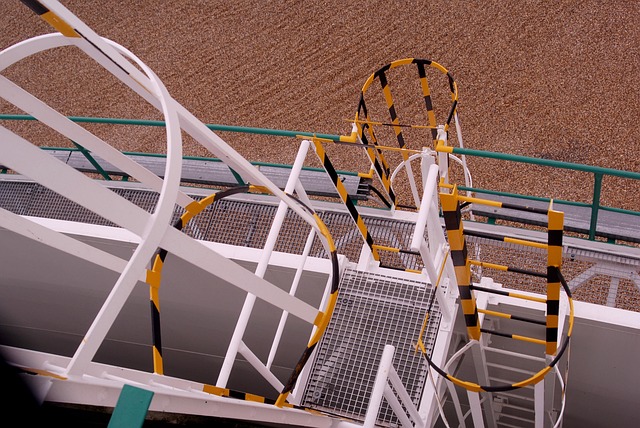

Design and Functionality of a Small-Scale Simulator Unit

A small-scale tank truck leak simulator unit is designed to replicate the conditions and challenges encountered during real-world tank truck leak training. This innovative prop serves as a versatile tool for professionals in the transportation, logistics, and environmental sectors. The simulator typically consists of a miniature tank truck model with integrated components that mimic the functionality of larger counterparts, including a leaking tank, piping system, and control valves.

Its primary function is to enable realistic leak detection and response training. Participants can practice identifying leaks, containing the spill, and implementing appropriate safety protocols without the risks associated with live demonstrations. The simulator’s design allows for precise control over leak rates and scenarios, providing a dynamic and interactive learning environment. This hands-on approach enhances understanding, improves reaction times, and ensures that personnel are well-prepared to handle tank truck leaks effectively in real-life situations, thereby enhancing safety and environmental protection measures.

Benefits and Applications in Real-World Scenarios

The small scale tank truck leak simulator unit offers numerous benefits, particularly in the realm of safety and efficiency for real-world applications. As a versatile tank truck leak training prop, it enables professionals to safely simulate various leak scenarios without risking exposure to hazardous materials. This cost-effective solution facilitates hands-on training, enhancing preparedness among personnel tasked with responding to tank truck leaks.

In real-world scenarios, such simulators prove invaluable for refineries, chemical plants, and other industrial facilities where large storage tanks and tank trucks are commonly used. By practicing leak response protocols in a controlled environment, teams can improve their coordination, refine emergency procedures, and mitigate potential environmental impact. This proactive approach to training fosters a culture of safety and ensures that personnel are equipped to handle leaks effectively, reducing risks both to human life and the surrounding environment.