Valve Leak Training Units (VLTUs) are innovative simulation tools for emergency response and industrial safety, offering a controlled environment to practice leak management without risking product or infrastructure. These units enhance problem-solving abilities, improve crisis management, and reduce response times, ultimately protecting lives and assets. Implementing VLTUs involves selecting high-quality equipment, setting up a safe training environment, calibrating the unit, training personnel, practicing protocols, and continuous evaluation. Case studies show their significant impact in industries like chemical plants, reducing response times and improving overall efficiency. VLTUs are an essential cornerstone in many industrial safety programs.

In today’s critical operations, efficient emergency product transfer is paramount. This article explores a game-changing solution: prop simulating emergency product transfer using Valve Leak Training Units (VLTUs). VLTUs offer a realistic, controlled environment for essential training, enhancing safety protocols and preparedness. Beyond theoretical knowledge, VLTUs empower professionals to navigate complex scenarios effectively. We’ll delve into the benefits, implementation strategies, and real-world case studies showcasing their transformative impact in industrial settings.

- Understanding Valve Leak Training Units: A Prop Simulating Emergency Product Transfer Solution

- Benefits of Using Valve Leak Training Units in Safety Protocols

- Implementing Valve Leak Training Units: Step-by-Step Guide

- Case Studies: Successful Integration and Impact of Valve Leak Training Units in Industrial Settings

Understanding Valve Leak Training Units: A Prop Simulating Emergency Product Transfer Solution

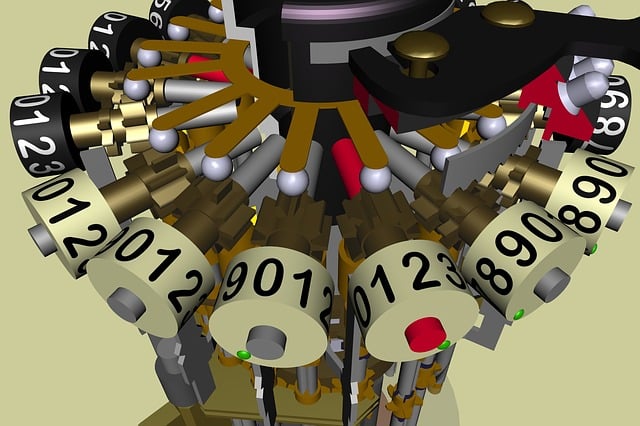

In the realm of emergency response and industrial safety, efficient product transfer is paramount, especially during critical situations. Here’s where Valve Leak Training Units (VLTUs) step in as a game-changer. These innovative simulation tools are meticulously designed to replicate real-world conditions, offering a controlled environment for training purposes. By simulating an emergency scenario with leaking valves, VLTUs enable technicians and first responders to practice their skills without risking any actual product or infrastructure.

VLTUs provide a vibrant and bustling landscape for learning, fostering a deep understanding of valve systems and leak management. They offer a laboratory-like setting where individuals can navigate a complex labyrinth of piping and valves, mimicking the challenges encountered during an actual emergency. This hands-on experience is invaluable, as it enhances problem-solving abilities and ensures that personnel are prepared to handle any potential leaks or product transfer issues promptly and effectively.

Benefits of Using Valve Leak Training Units in Safety Protocols

In the realm of emergency product transfer, proficiency in handling potential leaks is paramount for ensuring safety and minimizing risks. Valve leak training units play a pivotal role in enhancing this readiness by offering a controlled environment to simulate various leak scenarios. These units enable professionals to practice rapid response techniques, refining their skills in containing and mitigating leaks efficiently. This hands-on training is invaluable, as it allows teams to confront and overcome real-world challenges without endangering personnel or the surrounding environment.

Moreover, valve leak training units foster a culture of safety awareness. They provide a practical understanding of the unique dynamics involved in leak management, empowering employees to act swiftly and decisively during emergencies. This specialized training can significantly reduce response times and improve overall crisis management, ultimately safeguarding lives and assets.

Implementing Valve Leak Training Units: Step-by-Step Guide

Implementing Valve Leak Training Units is a crucial step in preparing for emergency product transfer scenarios. These units are designed to simulate potential leaks, allowing teams to practice response protocols and enhance their readiness. Here’s a step-by-step guide to help you through the process:

1. Select Appropriate Equipment: Choose high-quality valve leak training units that replicate real-world conditions accurately. Look for models capable of producing controlled leak rates and varying flow patterns to mirror different emergency scenarios.

2. Set Up the Training Environment: Create a safe, contained area where you can simulate an emergency transfer situation. Ensure proper ventilation and adhere to all safety protocols. Place the valve leak training unit at the center, connecting it to appropriate storage or collection systems as per your established emergency plan.

3. Calibrate and Test the Unit: Before training sessions, calibrate the unit to ensure precise leak control. Conduct test runs to verify the unit’s performance and make any necessary adjustments. This step is vital for accurate simulations.

4. Train Your Team: Familiarize your team with the valve leak training unit and its controls. Conduct hands-on training exercises, starting with basic leak scenarios and progressing to more complex situations. Encourage open communication and feedback during these sessions to improve overall response efficiency.

5. Practice Emergency Protocols: Utilize the valve leak training units to rehearse emergency product transfer procedures. Simulate various scenarios, such as unexpected leaks during transfers or equipment malfunctions, to ensure your team can quickly adapt and implement their protocols effectively.

6. Evaluate and Refine: After each training session, debrief with your team to discuss performance, identify areas for improvement, and update emergency response plans accordingly. Regular evaluation ensures that your team remains prepared for any eventuality.

Case Studies: Successful Integration and Impact of Valve Leak Training Units in Industrial Settings

In recent years, the integration of valve leak training units in industrial settings has been a game-changer in emergency product transfer simulations. These units have proven to be invaluable tools for preparing personnel to handle critical situations involving hazardous materials. Case studies from various industries highlight their successful impact. For instance, a major chemical plant implemented a rigorous training program utilizing valve leak training units, resulting in a significant reduction in emergency response times and improved overall efficiency during simulated leaks.

The training has been particularly effective in enhancing operator skills and decision-making abilities under pressure. By replicating real-world scenarios, workers can gain practical experience managing valve leaks without endangering themselves or the facility. This hands-on approach ensures that when an actual emergency arises, teams are better equipped to navigate complex situations swiftly and safely. The integration of these units has thus become a cornerstone in many industrial safety programs, underscoring their essential role in preparedness and response strategies.