Hazmat valve training equipment, powered by advanced technologies like MC306 hardware, is vital for industries handling hazardous materials. The MC306 offers immersive leak simulation scenarios with customizable settings, preparing personnel to respond swiftly and effectively in emergencies. By replicating real-world conditions without exposing trainees to risks, this equipment enhances safety skills, improves crisis management efficiency, and contributes to environmental protection. Best practices include meticulous setup, comprehensive training, regular maintenance, and post-exercise debriefings for optimal learning and continuous improvement.

In today’s safety-conscious environment, effective Hazmat valve training is paramount. This article explores a powerful tool in the fight against hazardous leaks: the Hazmat Valve Training Prop with MC306 hardware. We’ll delve into the significance of specialized training equipment, dissecting the unique features and advantages of MC306. Through an integrated approach, we’ll demonstrate how this system enhances leak response readiness. Additionally, best practices will be outlined for maximizing its potential, ensuring professionals are equipped to handle any hazardous scenario.

- Understanding Hazmat Valve Training Equipment: A Vital Component in Safety Measures

- MC306 Hardware: Features and Benefits for Effective Leak Training

- Integrating Valve Leak Training with MC306: A Comprehensive Approach

- Best Practices for Utilizing Hazmat Valve Training Prop with MC306 Hardware

Understanding Hazmat Valve Training Equipment: A Vital Component in Safety Measures

Hazmat valve training equipment plays a pivotal role in ensuring safety protocols within industries dealing with hazardous materials. This specialized gear is designed to simulate real-world scenarios, enabling personnel to practice and perfect their response techniques swiftly and effectively. By employing advanced technologies like MC306 hardware, organizations can implement immersive training programs that prepare employees for unexpected events involving toxic or flammable substances.

The integration of such equipment is not merely a compliance requirement but a proactive measure to safeguard lives and minimize environmental impact. Regular training sessions with Hazmat valve simulation systems foster a culture of preparedness, allowing workers to recognize potential risks, operate valves correctly, and evacuate areas promptly during emergencies. This, in turn, contributes to the overall efficiency of crisis management and accident prevention protocols.

MC306 Hardware: Features and Benefits for Effective Leak Training

The MC306 hardware is a cutting-edge innovation in hazmat valve training equipment, designed to revolutionize leak training simulations. This advanced system offers a comprehensive solution for safety professionals, providing realistic and immersive training experiences. Its key features include customizable settings, allowing trainers to simulate various leak scenarios, from minor drips to critical releases, ensuring individuals are prepared for every eventuality.

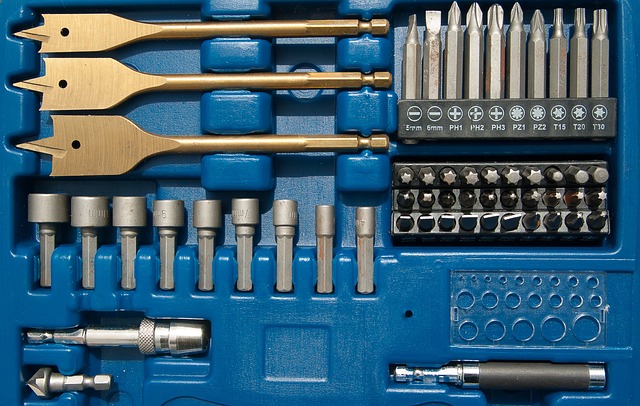

With its robust design, the MC306 hardware ensures accurate pressure control and precise flow rates, mimicking real-world conditions. This level of realism is crucial in hazmat valve training, enabling trainees to develop confidence and refine their skills without risking exposure to hazardous materials. The system’s modularity also facilitates easy setup and maintenance, making it a versatile tool for diverse training environments.

Integrating Valve Leak Training with MC306: A Comprehensive Approach

Integrating Valve Leak Training with MC306 hardware offers a comprehensive solution for enhancing safety in hazardous material handling. The MC306, known for its advanced capabilities, serves as a powerful tool to simulate real-world scenarios, enabling trainees to practice valve leak response procedures effectively. This training equipment is designed to replicate various leak conditions, allowing professionals to develop critical skills under controlled circumstances.

By combining cutting-edge technology with specialized hazmat valve training, organizations can ensure their personnel are well-prepared for potential emergencies. Trainees gain hands-on experience in a safe environment, learning to identify leaks, activate emergency protocols, and contain the situation promptly. This proactive approach not only complies with safety regulations but also fosters a culture of preparedness among workers, ultimately contributing to more efficient and effective incident management.

Best Practices for Utilizing Hazmat Valve Training Prop with MC306 Hardware

When utilizing Hazmat Valve Training Props with MC306 hardware, adherence to best practices is paramount for effective and safe learning experiences. Begin by ensuring proper setup and calibration of the equipment. Each component, from valves to connectors, should be thoroughly inspected and aligned according to manufacturer guidelines. This guarantees accurate simulations that accurately mimic real-world scenarios. Additionally, provide comprehensive training sessions for all participants. Understanding the hardware’s functionality, safety protocols, and emergency procedures is crucial.

Encourage realistic practice scenarios to optimize learning outcomes. Simulate various situations, such as different types of leaks or pressure surges, to familiarize users with appropriate responses. Regular maintenance and prompt repair of any identified issues are essential. Keeping the training equipment in top condition ensures reliable performance during critical exercises. Incorporate debriefing sessions after each exercise to reinforce lessons learned and identify areas for improvement. This iterative approach enhances proficiency in handling Hazmat valve training equipment, ultimately fostering a culture of safety within your organization.