Emergency valve dome props revolutionize clamp application training by offering immersive, hands-on experiences in controlled settings. In industrial safety management, these tools enable quick system shutdowns during emergencies, minimizing downtime and damage. They prioritize efficiency and safety through adaptable, durable designs that withstand harsh conditions. Proper selection, installation, and maintenance ensure their longevity and reliability. Best practices integrate dome props into training programs, enhancing operational resilience across sectors like oil and gas. Future innovations focus on smart sensors for real-time monitoring and sustainable materials, promising a safer, more environmentally friendly future for critical applications.

“Unleashing efficient industrial training with the versatile emergency valve dome prop – a game-changer in clamp application processes. This article delves into the multifaceted role of this hardware, exploring its significance in safety measures and operational efficiency. From understanding the basics of dome props to their real-world applications and future innovations, we uncover why these tools are essential for industrial professionals. Discover how emergency valve dome props enhance training, improve performance, and shape the future of industrial practices.”

- Understanding Emergency Valve Dome Props: A Essential Tool for Clamp Application Training

- The Role of Dome Hardware in Enhancing Safety Measures

- Benefits of Using Emergency Valve Dome Props in Industrial Settings

- Selection and Installation Guidelines for Optimal Performance

- Real-World Applications: Success Stories and Best Practices

- Future Trends and Innovations in Dome Prop Technology

Understanding Emergency Valve Dome Props: A Essential Tool for Clamp Application Training

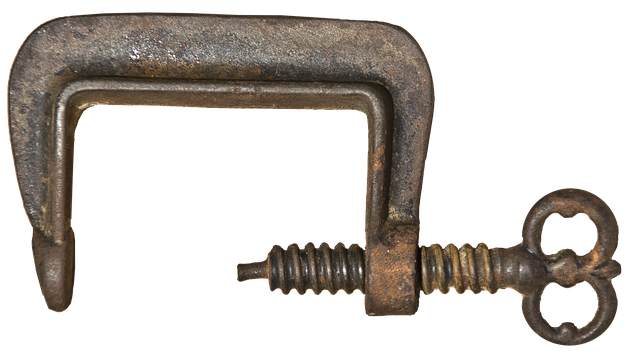

In the realm of clamp application training, understanding and utilizing emergency valve dome props is a game-changer. These specialized tools serve as essential components in simulating real-world scenarios, enabling trainees to gain practical experience in a controlled environment. An emergency valve dome prop replicates the critical function of a valve system, allowing participants to practice rapid and accurate clamp application techniques under pressure. By training with these props, folks can enhance their problem-solving skills and adaptability, ensuring they’re prepared for any unexpected challenges that may arise during actual operations.

In today’s digital era, it’s crucial to emphasize the significance of such hands-on training. Unlike theoretical knowledge, practicing with emergency valve dome props enables a multifaceted learning experience. Trainees not only understand the theory but also develop muscular memory, reaction time, and the ability to make split-second decisions. This holistic approach fosters confidence and proficiency, making them ready to navigate labyrinthine situations with ease and precision, especially in high-pressure environments where every second counts.

The Role of Dome Hardware in Enhancing Safety Measures

In the realm of clamp application training with dome hardware, the role of emergency valve dome props cannot be overstated. These specialized components are designed to enhance safety measures by providing a quick and reliable means of isolating high-pressure systems during emergencies. By seamlessly integrating into the training process, dome props teach users how to respond swiftly and effectively in critical situations, ensuring minimal downtime and potential damage.

The strategic placement of emergency valve dome props allows for controlled system shutdowns, preventing catastrophic failures. Their robust construction and reliable operation are pivotal in fostering a culture of safety within industrial settings. As professionals navigate complex scenarios, the familiarity with dome hardware, including its proper use and maintenance, becomes a game-changer, ultimately safeguarding personnel and infrastructure alike.

Benefits of Using Emergency Valve Dome Props in Industrial Settings

In industrial settings, where safety and efficiency are paramount, emergency valve dome props play a crucial role in ensuring smooth operations. These specialized hardware components are designed to securely fasten and support various structures, particularly during critical maintenance or emergency situations. One of the key benefits is their ability to provide temporary yet robust solutions, allowing for easy access and manipulation of valves and other essential equipment. By employing emergency valve dome props, workers can quickly and safely isolate specific sections for repair or replacement without disrupting the entire system.

Moreover, these props offer a range of advantages in terms of adaptability and longevity. Their versatile design enables them to fit diverse valve configurations, ensuring compatibility across various industrial applications. Additionally, high-quality emergency valve dome props are built to withstand harsh conditions, including extreme temperatures and corrosive environments, making them reliable companions for continuous use over extended periods. This reliability translates into reduced downtime and lower maintenance costs for industries relying on efficient and safe processes.

Selection and Installation Guidelines for Optimal Performance

When selecting clamp application training props with dome hardware, especially for emergency valve dome props, it’s crucial to consider factors that ensure optimal performance. The fit and compatibility of the components are key; ensure the props match your specific valve model and size precisely. Using the right materials also significantly impacts durability and reliability, particularly in harsh environments where corrosion resistance is vital.

Installation should be done meticulously by trained personnel to avoid damage or misalignment. Proper alignment guarantees secure closure and prevents leaks. Regular maintenance and inspection are equally important to catch any wear or damage early on. This includes checking for loose connections, corroded parts, and ensuring all bolts are securely fastened. Such proactive measures will extend the lifespan of your emergency valve dome props.

Real-World Applications: Success Stories and Best Practices

In various industrial sectors, the strategic application of clamp training props with dome hardware has led to significant improvements and success stories. One notable area is in the management of emergency valves, where dome props play a crucial role in ensuring swift and controlled access during critical situations. For instance, in oil and gas facilities, these props facilitate safe and efficient closure or opening of emergency valves, minimizing potential hazards and maximizing operational resilience.

Best practices often involve integrating dome prop systems with comprehensive training programs. This involves simulating real-world scenarios to familiarize personnel with the equipment’s functionality and response mechanisms. Regular drills and exercises help in identifying optimal deployment techniques, enhancing team coordination, and fostering a culture of safety. Moreover, maintaining proper maintenance routines for dome props guarantees their reliability during high-pressure situations, making them indispensable tools in modern industrial safety management.

Future Trends and Innovations in Dome Prop Technology

The future of dome prop technology looks promising, with innovations aimed at enhancing safety and efficiency in various industries. One exciting trend is the development of smart emergency valve dome props that integrate advanced sensors and connectivity. These props can monitor pressure levels, detect leaks, and remotely trigger shut-off mechanisms during emergencies, ensuring swift response times and minimizing potential hazards.

Additionally, researchers are exploring sustainable materials for dome prop manufacturing. Biodegradable and eco-friendly alternatives to traditional prop materials not only reduce environmental impact but also offer cost-effective solutions. As the demand for green technology grows, these innovations will play a crucial role in shaping a more sustainable future for dome prop applications, especially in critical sectors like oil and gas, where emergency valve dome props are indispensable.