In today's digital era, comprehensive emergency offloading training for tanker product removal is vital for industrial operations' safety and efficiency. An Emergency Tanker Offloading Training Unit (ETOTU) equips personnel to handle hazardous materials securely, minimizing risks and complying with regulations. This unit features robust piping systems, versatile pump systems, and advanced control mechanisms, along with safety features like emergency shut-off valves. Training in these units prioritizes safety through controlled simulations of various products and scenarios, enhancing learning and familiarizing participants with protocols and equipment use. Proven effective in industries like oil and gas, emergency offloading training units improve reaction times and resource deployment during incidents, fostering operational efficiency and preparedness. When selecting a provider, look for hands-on experience in realistic scenarios, customized industry needs, regular updates, and quality assurance checks.

In the high-stakes world of hazardous material transport, effective emergency offloading training is paramount. This comprehensive guide explores the vital role of an emergency offloading training unit, delving into its components, safety protocols, and real-world applications. We’ll navigate best practices, dissect case studies, and guide you in selecting the right providers and tools to equip your team with the skills needed for swift, safe, and efficient emergency offloading responses.

- Understanding the Need for Emergency Offloading Training

- Components of an Effective Emergency Tanker Offloading Unit

- Safety Measures and Best Practices for Training

- Real-World Applications and Case Studies

- Choosing the Right Training Provider and Tools

Understanding the Need for Emergency Offloading Training

In today’s digital era, where efficiency and safety are paramount in industrial operations, the need for comprehensive emergency offloading training for tanker product removal cannot be overstated. This specialized training unit equips personnel with the knowledge and skills to handle critical situations involving hazardous materials, ensuring swift and secure responses that minimize risks and protect both workers and the environment.

Emergency offloading training is essential due to the inherent complexities of tanker product removal. It involves navigating labyrinthine processes, understanding the unique properties of various products, and mastering safety protocols to prevent accidents and mitigate potential disasters. By investing in this training, companies not only comply with regulatory requirements but also foster a culture of preparedness, enhancing their operational resilience and the well-being of their workforce.

Components of an Effective Emergency Tanker Offloading Unit

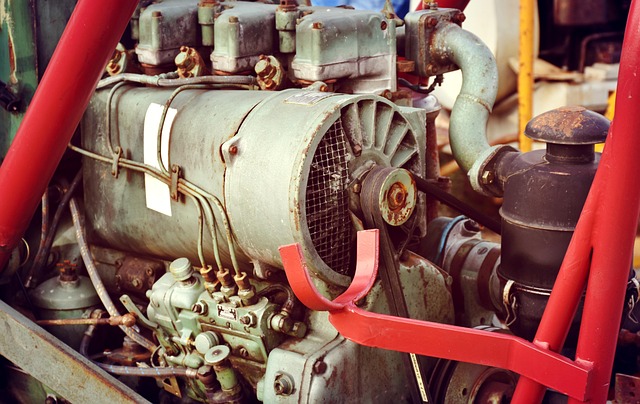

An effective Emergency Tanker Offloading Training Unit (ETOTU) should be equipped with several key components to ensure safe and efficient product removal in critical situations. Firstly, it must incorporate robust and reliable piping systems designed to withstand high-pressure conditions and various types of fluids. These pipes should allow for flexible connections, enabling easy navigation around tight corners within the tanker or in confined workspaces.

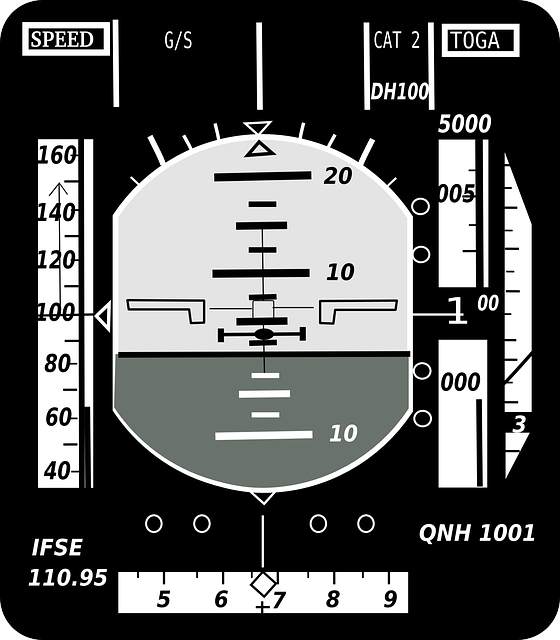

Secondly, a versatile pump system is essential. This should be capable of handling different product viscosities and densities while maintaining optimal flow rates. The ETOTU should also include advanced control mechanisms that enable precise monitoring and adjustment of offloading parameters, such as pressure, temperature, and flow velocity. Additionally, safety features like emergency shut-off valves and alarms are critical to mitigate risks associated with hazardous materials.

Safety Measures and Best Practices for Training

When conducting emergency tanker product removal training, safety should always be the top priority. Utilizing a dedicated emergency offloading training unit allows for a controlled and secure environment where personnel can practice critical skills without risking real-world hazards. These units are designed to mimic the conditions of an actual tank farm, complete with realistic simulation of various products and potential leaks. This not only enhances learning but also ensures that every participant is familiarized with safety protocols, emergency response procedures, and proper use of equipment.

Best practices for such training include ensuring all personnel are adequately trained in the specific product handling procedures, as well as equipping them with appropriate personal protective equipment (PPE). Regular maintenance and calibration of the training unit itself are also essential to guarantee accuracy and reliability. Additionally, conducting these sessions under different scenarios—from minor spills to major emergencies—enables trainees to develop versatile skills that can be applied in a wide range of situations.

Real-World Applications and Case Studies

In real-world applications, emergency offloading training units have proven invaluable in preparing personnel for high-pressure situations involving product removal from tankers. These scenarios often occur in industries such as oil and gas, where rapid and efficient response is critical to prevent environmental damage and ensure worker safety. Case studies highlight the success of these training programs in enhancing incident management capabilities. For instance, a recent study showed that companies utilizing specialized emergency offloading training have demonstrated faster reaction times and more effective resource deployment during simulated tanker incidents.

The practical implementation of such training units has led to significant improvements in overall operational efficiency. By replicating real-world challenges, including the complexity of different product types and tank configurations, trainees gain hands-on experience that translates directly into better decision-making under stress. This proactive approach to emergency preparedness is especially crucial in dynamic industries where rapid response can mitigate risks and minimize disruptions.

Choosing the Right Training Provider and Tools

When selecting a provider for emergency tanker product removal training, it’s paramount to choose an organization with specialized expertise and state-of-the-art equipment, such as an emergency offloading training unit. Look for providers who offer hands-on experience in realistic scenarios, ensuring your team is well-prepared for any on-site challenges. A reputable training unit should include features like simulated tanker interfaces, hazardous material handling modules, and interactive safety protocols to offer a comprehensive learning environment.

Additionally, consider the provider’s ability to customize programs based on specific industry needs. Reputable trainers often provide ongoing support, regular equipment updates, and continuous quality assurance checks. These aspects are crucial in ensuring your team receives the most effective and current emergency offloading training, fostering a culture of safety within your organization.